Introducing the MLCe

The MLCe, with its lower machine height, touch-screen interface and accessibility, ensures compliance with the ergnomic requirements of the user and offers a good overview and easy access to all tools. The touch-screen technology enables the operator to work in an intuitive and efficient way. Superior lens surface quality, precision and productivity are the much valued and given features of all types of DAC lathes.

The MLCe, with its lower machine height, touch-screen interface and accessibility, ensures compliance with the ergnomic requirements of the user and offers a good overview and easy access to all tools. The touch-screen technology enables the operator to work in an intuitive and efficient way. Superior lens surface quality, precision and productivity are the much valued and given features of all types of DAC lathes.

Precision air bearing spindles and slides are the main pre-requisites for achieving superior surface quality for contact lenses and intra-ocular lenses.

The DAC compact tool holders and the latest in DAC software for managing multiple tool functions provide the best opportunity to make the most of the large tool plate on the ALMe, in order to produce highly individual intra-ocular lens designs.

The various options let you redefine your processes: Whether you require high volume output or polish free capable surfaces at reduced speeds and feeds, the MLCe offers these possibilites.

The well known MLC with its higher granite is still available for those who want to have a matching look with their already existing machines in the lab.

Benefits

- Where Premium lenses are required or space is limited.

- Complex lens types can be made in a single machine set-up without the need for specialized part registration.

- Additional options can be added for diagnostic marking or product ID.

- Capacity increase easily achieved by adding tray-fed autoloader option.

- All air-bearing axes for superior surface finish quality.

- Haptic Air-bearing milling spindle with chiller provides improved accuracy and repeatability.

- IOL software includes traditional designs, additional software modules allow for customized designs.

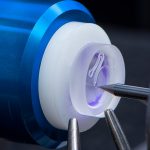

On-Lathe Milling

The MLCe allows for on lathe haptic milling. This method reduces the registration errors associated with moving parts from one machine to another. Lathing and milling are performed in-situ. This is especially important when making toric lenses for example.

Whether the process involves using pre-blocked, semi-finished parts or wax blocked blanks the MLCe can be used as the primary optic and haptic generator.

IOL PM Suite

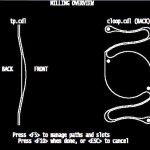

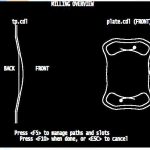

Unique to DAC and written by our own software architects, the IOL Program Module (PM) Suite enables the user to program both optic and haptic parameters. Most haptic designs can be generated, whether the traditional C-loop or more advanced Quad-haptic designs. The Toric function controls the design and orientation of the toric zone within the lens . Refractive, multifocal and combined designs are available as standard.

Other design capabilities are feasible, including but not limited to: A-toric (A-Conic), Diffractive multifocal and LRTS file support.

From lens design to manufacture, the DAC IOL PM Suite automatically calculates all desired toolpaths and incorporates blending capability in a single step, further simplifying lens production

Options

Please click on these links to see detailed descriptions of our available options:

ALMe/ALM & MLC Options

Universal 1000 Autoloader

Technical Data

Precision air-bearing spindle

Air-bearing AC induction motor spindle, with recirculating chiller for operational stability

(software limited)

(0.5 in x 0.5 in) with dead length stop.

Specials supplied upon request

Inflated: Isolates frequencies above 7 Hz

(Deflated: Naturally isolates frequencies above 14 Hz)

Installation Data

Recommended air quality: Class 2 per ISO 8573-1:2010

(W x D x H)

(W x D x H)

Shipping 1300 kg

2800 lb

Additional Photos