IOL and CL Manufacturing

IOL and CL Manufacturing

There is no one process that is the same as the next, but every lens should be handled with equal care and attention.

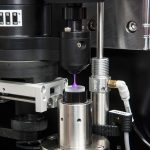

The DAC Precision Blocker is a ‘no-compromise’ solution to your lens process needs whether you are making high volume stock product or individual prescriptions.

Whether the lenses are Soft, GP, Scleral or even IOL, the DAC Precision Blocker is built to deliver accurately and consistently on concentricity, tilt and squareness.

The high precision blocker was developed to maximize the full potential of the DAC lathe’s edge contouring capability.

First or second side part handling is blocked with a high degree of accuracy and repeatability, with the minimum of time and operator attention. It offers universal blocking applications for a wide variety of lens types and processes.

The DAC Precision Blocking System is designed with collets that have the same high accuracy as the DAC lathe collets.

Easily inter-changeable wax pots give the opportunity to work with a variety of different waxes according to your needs and reduces down time for change-overs.

The on-board timer for the wax pot warm-up, using different time settings for each work day, allows you to start your work without any waiting time.

An LCD touch screen provides an intuitive interface that allows the user to optimize variables to suit the individual process needs.

From the main menu all important parameters can be accessed to switch between different possibilities such as blocking with tape or wax, selecting different blocking tables or using the wax air cooler.

Each of the six blocking tables have independently configurable parameters.

Benefits

- Fast, reliable calibration

- Safe, consistent wax dosing

- Timer for wax pot warm-up to give you a fast start

- Quick and easy inter-changeable wax pots minimize down-time when switching between wax types

- LCD touch screen with intuitive user interface

- Strong, stable construction

The DAC Precision Blocking System is designed and robustly built, to maintain micron accuracy and repeatability.

All operational functions are highly intuitive and software controlled by a PLC.

Settings, such as wax temperature, volume, cool down times etc, are easily set, monitored or changed utilizing a colored touch screen interface, incorporated into the front of the machine. The machine can accommodate blocking ½” material buttons with wax or tape, finished base curve arbor blocking or transfer blocking arbor to arbor. Each blocking system is supplied with two, interchangeable wax pot, dispense assemblies and heat sink stands, to use with your hotplate and facilitate the use of different wax types.

With the DAC Precision Blocking System, you can take full advantage of your DAC lathe’s capabilities and produce lenses with fully contoured, finished edges with confidence.

Technical Data

76.2 mm (3.0 in)

Installation Data

Recommended air quality: Class 4 per ISO 8573-1:2010

(W x D x H)

(W x D x H)

Shipping 114 kg

250 lb

IOL and CL Manufacturing

IOL and CL Manufacturing